Feeder

We support the supply of soft packaging smoothly by combining it with a direct thermal printer or auto labeler.

We also offer feeders with an innovative feed function that enables the transport of stepped zippered packaging bags that have been considered difficult.

Auto feeder

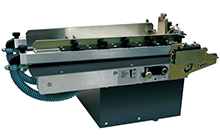

AFB-350Ⅱ

Cost-effective standard feeder (belt type) corresponding to various works

The product supplies from the lower belt. Since the soft packaging can be stacked and set before they run out, it continuously works without stopping the machine.

Supply recommended work

For thick work such as three-sided bag (nylon poly, laminate, aluminum bag), paper, etc.

About separation structure

The rollers of all machines, such as various feeders, empty bag labels, and direct thermal printers, rotate in the positive direction toward stacker side in order to flow the work (bag). However, there is only one roller that rotates in the reverse direction.

We call it “reverse roller”.

Adjust the height of the work (bag) to pass through only a small gap between the reverse rotation roller and positive rotation roller just below it. Through just one sheet, it is a mechanism to return the second and subsequent sheets by the function of the reverse rotation roller.

In fact, the same system is introduced in a machine which count money.

Image of separation structure

Elevator air feeder

EF-500

It can be mounted in large quantities, and it is a solid work supply type (belt type) such as a three-sided bag.

The supply unit for setting the soft packaging bags is an elevator mechanism, and it can be set in large quantities because it is a top extraction type.

It makes a large amount of work loaded by supplying the upper belt.

Supply recommended work

For thick work such as three-sided bag (nylon poly, laminate, aluminum bag), paper, etc.

Elevator feeder

EF-500A

It can be mounted in large quantities, and it is a solid work supply type (belt type) such as a three-sided bag.

The supply unit for setting the soft packaging bags is an elevator mechanism, and it can be set in large quantities because it is a top extraction type.

It makes a large amount of work loaded by supplying the upper belt.

Compressed air is blown out strongly from both sides, thin and large bags are separated and floated, and suctioned and supplied by a vacuum rotor.

Processing is much faster than other companies’ supply of suction pad method. It is because the roller which sucked up the packaging material rotates and bridges to the next roller.

Supply recommended work

For thin work such as Polyethylene Tube (50 u or more)

Auto feeder

AFZ-350

Feeding machine with elevator device capable of transporting packaging bags with zipper

We also offer feeders with an innovative feed function that enables the transport of stepped zippered packaging bags that have been considered difficult.

Since you can supply from the open side of bags, you have wide range of options of print location.

A flat flexible packaging bag can be set in large quantities by using the elevator mechanism to set the feeding unit.

Supply recommended work

For thick work such as chuck bag, laminated three-way bag, paper, etc.

Air feeder

AF-400Ⅱ

Air vacuum rotor supply device with thin work supply type (Air type)

By blowing compressed air strongly from both sides, thin and large packaging bags are also floated up and suctioned/supplied by a vacuum rotor.

Because the roller that sucks the packaging bag rotates as it is and bridges to the next roller, the processing capacity is much faster than the other company’s supply of suction pad method.

Supply recommended work

For thin work such as polyethylene (more than 50u) tube bag

Stacker

We support for stocking at the end part of direct thermal printer and auto labeler. We also offer stackers that can stock thin bags or remove static electricity.

Belt stacker

BS-350Ⅱ

High performance stacker with optional antistatic device

The packaging bags only drop under its own weight after the last roller of the printer or labeler. By introducing this belt stacker, thin bags can be aligned and stacked as they are transported while being held between belts.

By installing an optional antistatic device, you can remove static electricity from the bag and align the bag.

Elevator stacker

ES-500

A type that can be mass-processed in combination with an elevator feeder

This stacker can adjust the load according to the work.

It removes static electricity and aligns the packaging by introducing optional static antistatic device.

We recommend you to use this device with a supply feeder (EF-500 / EF-500A / AFZ-135).

[Option] Antistatic device

The small, high-performance bag is discharged in a smooth state to the tray.

You can mount a compact bar type antistatic device into the stacker (BS-350 / ES-500). It’s a direct connection type with a large amount of ion generation, and ideal for large charged objects. It greatly helps to solve the problem of uneven electricity removal.

The discharged bags are pushed out to the tray of the saucer in a smooth state.

Specifications (It may be different depending on the destination country.)

| Model | Zipper bag feeder | Zipper bag feeder | Elevator air feeder | Air feeder | Zipper bag feeder |

| AFB-350Ⅱ | EF-500 | EF-500A | AF-400Ⅱ | AFZ-135 | |

| Work size | 70~340(W)×90~400(L) | 90~320(W)×90~400(L) | 80~320(W)×90~480(L) | 110340(W)×190~297(L) | |

| Capacity | 15~60 sheets/min ※1 | 145~295mm/sec ※1 | |||

| Feed method | Bottom out belt type | Top belt | Top vacuum rotor removal | Lower surface vacuum rotor removal | Rubber belt |

| Load capacity | 120mm(MAX・Height) ※2 | 130mm(MAX・Height) ※2 | 40mm(MAX・Height) ※2 | Approx.100 sheets ※2 | |

| External dimensions (mm) | 460×270×300 | 500×570×300 | 540×470×340 | 490×670×340 | 450×630×310 |

| Power supply | AC100V・20W・50/60Hz | AC100V・30W・50/60Hz | AC-100V・20W | AC-100V・20W・ 50/60Hz | |

| Weight | 8kg | 20kg (without air pump) pump: 1200W) | 0kg (without air pump) pump: 1500W) | 17.5kg | |

| Option | Thin belt, cam | – | |||

※1 Processing capacity changes according to work size. The smaller the size of the work, the greater the amount of processing it becomes.

※2 Load capacity changes depending on the condition of work such as presence of powder, packaging for automatic machine, strength of waist, and seal method.

※Specifications are subject to change without notice.

Stacker

| Model | Elevator stacker | Belt stacker |

| ES-500 | BS-350Ⅱ | |

| Work size | 90~320(W)×90~400(L) | |

| Capacity | 15~90 sheets/min ※1 | |

| External dimensions (mm) | 480×370×420 | 420×355×262 |

| Power supply | AC100V・15W・50/60HZ | AC100V・15W・50/60HZ |

| Weight | 15kg | 4kg |

| Option | Antistatic device | |

※1 In the situation there is no damage due to dust or foreign matter (and depending on the driving conditions)

※2 Fonts are different from designated PC software. Some abbreviations, non-correspondence, etc. may differ from those displayed on the PC.

※3 Black character rate 40%

※4 Print quality excluded